Best price centrifugal egg liquid separating beating machine duck

egg breaking cracker machine

Product description

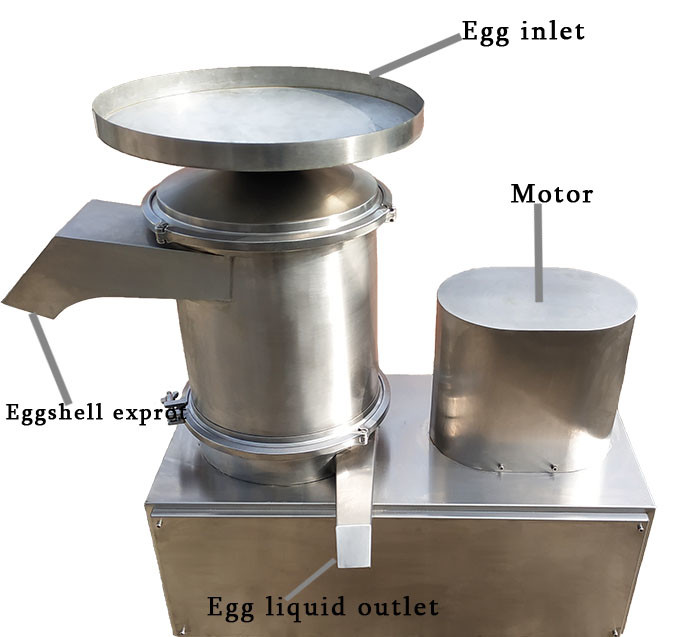

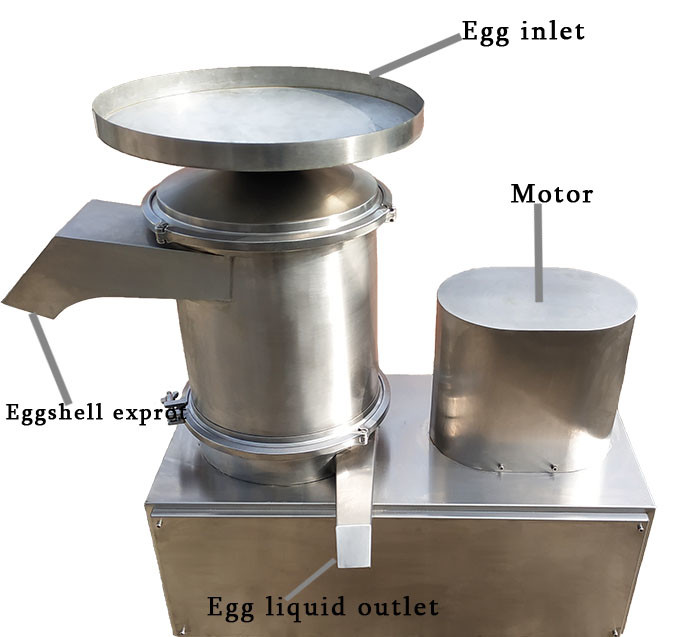

Introduction of commercial egg beating cracking machine:

The commercial egg beater adopts a vertical twisting cage

self-lifting structure, and the mesh screen is swept away. Just put

the cleaned eggs into the funnel, and the machine will generate

centrifugal action through accelerated rotation, which will

automatically break the eggs and separate the egg shell from the

egg liquid. The egg liquid flows out from the discharge port,

and the egg shell is lifted by the twisting cage and discharged

from the waste port, which saves labor and has high egg liquid

extraction efficiency. This machine is widely used in small and

medium scale food factories. The operation of the machine is simple

and fast, the failure rate is low, and the whole machine is made of

stainless steel, which is easy to disassemble and assemble, and

easy to clean.

Features of automatic egg beating machine:

1. It adopts special centrifugal mechanism design, and the material

is all made of 304 stainless steel. The humanized design is

convenient for disassembly and assembly, and it is easy to clean.

2. Slotting screen adopts slot screen structure, which has higher

mechanical strength than flat screen, is not easy to damage, not

easy to block, and the egg liquid filter is better, and there is no

granular impurities.

3. The egg shell is automatically lifted by the vertical twisting

cage and discharged through the egg shell discharge port. In this

way, only 1% of the egg liquid remains in the egg shell, which

greatly improves the egg liquid collection rate. At the same time,

because the egg shell is crushed, the volume is reduced, and the

emission reduction is realized.

4. The equipment has a large output and can process 10000-18000

fresh eggs per hour.

5. The equipment is small in size, does not require a large

workshop, and requires little investment in capital construction.

6. The investment is small, and the price of this equipment is

cheaper than that of the BK type egg beater with the same output.

| Model | AH-DDJ-300 |

| Capacity | 10000-18000pcs/h |

| Egg liquid acquisition rate | 97%-99% |

| Power | 2.2KW |

| Voltage | 380V/50HZ |

| Machine size | 900*600*1200mm |

| Weight | 130kg |

Company information

Luohe Aihe Mechanical and Electrical Equipment Co., Ltd. is located

in China's food city Luohe city with prosperous economy and

developed transportation. It is a professional manufacturer engaged

in the research and development and sales of all kinds of food

machinery, with skilled professional and technical personnel and

advanced production and processing equipment. The company has been

committed to the development of food machinery and new technology

of food machinery, leading products are: daily processing 6-1000

tons of series of grain deep processing machinery, food machinery,

series of food cleaning equipment, series of food cleaning

conveying equipment, series of quantitative packaging scale

equipment, series of environmental protection dust removal

equipment and other mechanical products. Products are sold all over

the country and get the majority of users' praise and love.

FAQ:

Q1: Are you a trade company or a manufacturer?

A1: we are a manufacturer, welcome to visit our factory and check

the machines.

Q2: How long is your delivery time?

A2: Generally it is 5-10 days if the goods are in stock. or it is

20-35 days if the goods are not in stock, we could discuss

beforecontract.

Q3: Could you supply all the parameters about the machines?

A3: Yes, we will supply all the parameters, price, layout drawing,

factory design etc.

Q4: What is your terms of payment ?

A4: 30% T/T in advance , 70% balance before shipment after

inspection.

Q5: How about the after-service?

A5: We will send 1 engineer to the buyer's factory for 7-14 days

period installation and training to the operators.

Q6:do you supply any formula to buyer?

A6: yes, we supply formulas to buyer.

Q7: How about the machine warranty?

A7: We provide 1 year warranty, Lifetime service